RECOMMENDATION FOR VACUUM CASTING

As a consequence of pouring in the relatively poor vacuum the surface of the falling liquid is covered with an oxide film which naturally becomes entrained as bifilms. Can be easily pigmented with CP Colors dedicated especially for pigmenting of Sika vacuum casting resins.

Vacuum Die Casting An Overview Sciencedirect Topics

Can be easily pigmented with CP Colors dedicated especially for pigmenting of Sika vacuum casting resins.

. Get it as soon as Fri Feb 25. OrangeA Vacuum Investing Casting 2L Vacuum Casting Machine with 3 CFM Pump Casting and Investing Machine for Invested Flasks and RTV Molds. Vacuum Casting process or Urethane Casting process as it is also known is suitable for the production of a small quantity of injection moulded components with the quality of injection moulded parts without the level of financial investment required for tooling development.

Casting Part II. Hardness 60 Shore A. You dont need to let the silicon cure while under vacuum.

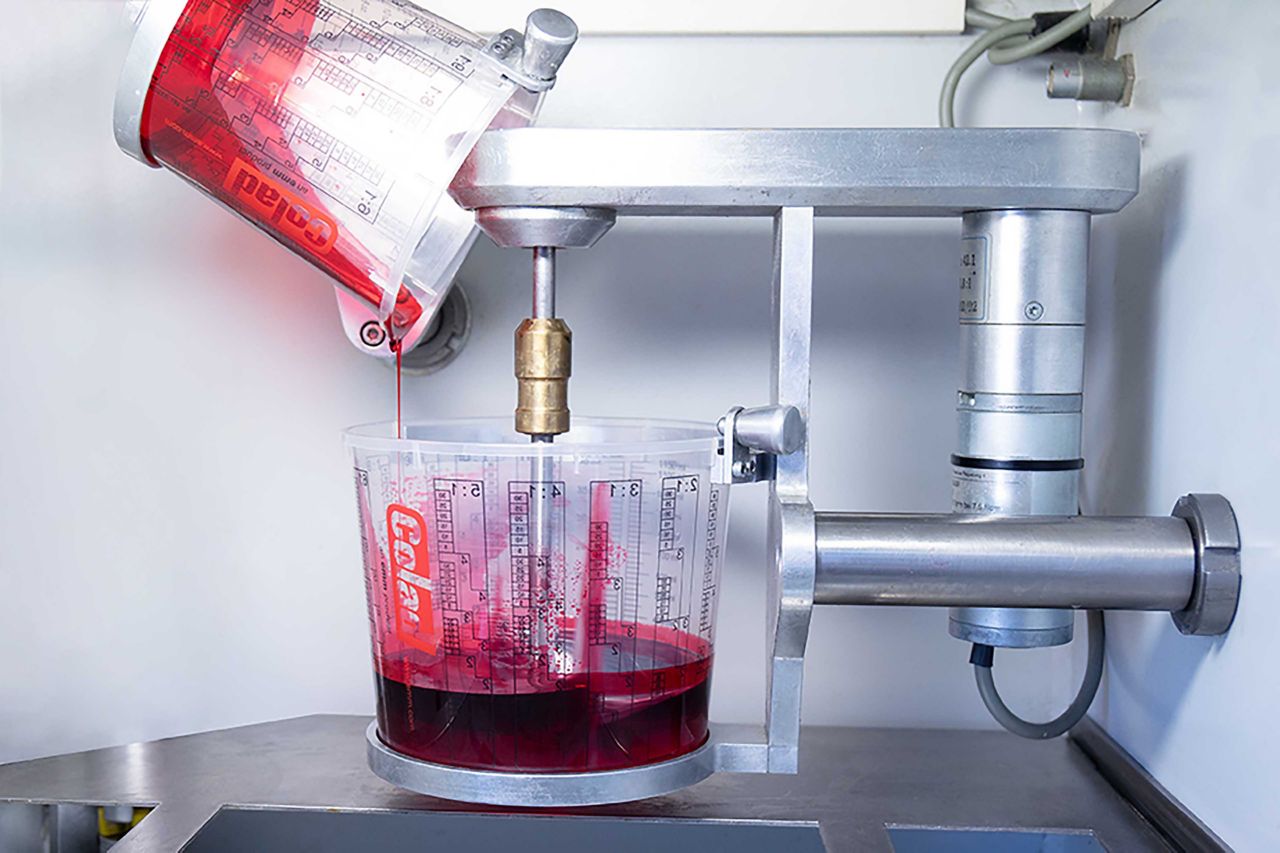

You will only use the vacuum chamber to remove the bubbles in the silicon before you pour it into the mold. This chart includes both SI units and Imperial or US customary units used to measure pressure. For resin you require 30 degrees Celsius to minimize shrinkage at vacuum pressure time of 5 min and a mold temperature of 60 degrees Celsius.

After adding electrical tape to the flask seam and side hole I melted 1 12 ounces of sterling silver turned on the vacuum and poured the molten metal. Increasing the pressure forces the resin into all the nooks and crannies of the mold. A heat-softened thin sheet 0003 to.

SuperbMelt jewelry casting machine SPB-DM can be used for casting any precious metal in the weight range of 1-6kg. This lessens the possibility of bubblesvoids in your molds. The vacuum in metal melting and casting operations can never be particularly good because of the natural and prolific outgassing of the refractories of the melting unit.

Flexural modulus 2 500 MPa. 38 out of 5 stars. The vacuum jewellery making machine is super jewellery casting machine you should opt for.

Fill Your Cart With Color Today. Melt metal in the handled crucible fluxing as needed. In vacuum casting youre require to have the correct optimum temperatures when curing the materials.

Low viscosity for easy casting. It is super-fast and energy efficient. Within a few seconds the vacuum gauge needle should indicate a vacuum of 20 inches at sea level or more which shows a good seal between the flask and pad.

A conversion chart for the units most commonly used to measure vacuum pressure. Polyurethane vacuum casting resin for technical parts and prototypes. The mold is placed in a vacuum chamber and filled with resin from an external hopper.

The size of the mold is limited by the dimensions of the vacuum chamber 1900 x 900 x 750 mm and by the volume of the product maximum volume. SI units are the International System of Units the modern form of the metric sy stem. Depending on the method the vacuum may be in the range from 40 to 03 newtons per sq m 03 to 2 10 -3 mm of mercury.

21800030 to the CASTING TABLE position. Just a quick note to say thanks for your help the castings look great and as. Vacuum Casting - Urethane Casting.

Applications of Vacuum Casting. Peak temperature 100 C. There might be three steps involved before you can have the final product but the process is swift and can deliver within the deadline.

Posted by 5 minutes ago. Purchase Advice US Close. Im also hoping to also vacuum the dog hair off my couch.

With years of expertise in the field we can fabricate your plastic parts to the highest standard as well as cost-efficient and with fast turnarounds. 3ERP is fully capable of handling your vacuum casting and silicone molding needs. 10 liters Typical quantities.

Good impact and flexural resistance. Tg 100 C. The time to manufacture depends on the desired characteristics of the part with.

Vacuum casting is a great method to make rigid or flexible parts and is ideal for high quality prototypes function. Vacuum casting is commonly used in combination with vacuum smelting for the production of shaped castings from special steels and alloys. Often you dont need to pull a vacuum on the resin just on the silicone used in the mold.

Pressure pots are used to cast. Vacuum is more of a step in casting bubble free since most materials will still have some bubbles after a vacuum is pulled. If you didnt catch the first post you might want to go here and read from the beginning.

Recommendation for a vacuum that works on laminate floors and my area rug. Read customer reviews find best sellers. Sand casting Vacuum Molding V-Process.

Ad Did You Check eBay. For best results we recommend a wall thickness of at least 15 mm. FREE Shipping by Amazon.

For those who work closely with the aerospace industry the term vacuum casting likely will be interpreted as the use of a vacuum during the melting of metal material. Up to 10 cash back A method used for casting fluid thermosetting resins to avoid inclusions of air bubbles. The Vacuum Casting process is typically used to produce small numbers usually up to 20 of polyurethane prototype parts.

Turn on the vacuum pump and turn the vacuum control knob No. Precious metals such as gold copper and silver or any other metal artwork can process with this product. Vacuum casting is ideal for rapid manufacturing or demands for short production runs.

It is a slightly slower process than SLA alone because of the additional steps involved in the process some of which are manually intensive. The pattern is specially vented so that a vacuum can be pulled through it. Vacuum is applied to pull out bubbles held until they have all risen to the surface then released.

Vacuum casting is the same as duplication using a silicon mold. Investment Casting from 3D Printed Wax This is the follow-up to a two-part blog installment the first part of which was shared last week. Then you should try vacuum casting.

Im also hoping to also vacuum the dog hair off my couch. Recommendation for a vacuum that works on laminate floors and my area rug. Ad Browse discover thousands of brands.

Crushing those last small bubbles and mold voids down is what the pressure chamber is for. It can be a preferred process for prototyping. Vacuum Casting Process.

Many of the complex alloys and superalloys such as titanium and nickel-based used in this industry are reactive with atmospheric oxygen or. Vacuum molding V-process is a variation of the sand casting process for most ferrous and non-ferrous metals in which unbonded sand is held in the flask with a vacuum.

Vacuum Die Casting An Overview Sciencedirect Topics

When To Use Pressure Pot And Vacuum Chamber

Pdf Vacuum Casting A New Answer For Manufacturing Biomicrosystems

Vacuum Casting Machine Instructions Shor International

When Is Vacuum Casting More Suitable Than Injection Molding 3erp

4l Jewelry Vacuum Casting Machine Vacuum Investing And Casting Machine Jewelry Lost Wax Cast Goldsmith Jewelry Casting Machine Machine Centre Aliexpress

Introduction To Vacuum Casting For Jewelry Youtube

Vacuum Molding Explanation Advantages And Disadvantages Mechanicalbase

Belum ada Komentar untuk "RECOMMENDATION FOR VACUUM CASTING"

Posting Komentar